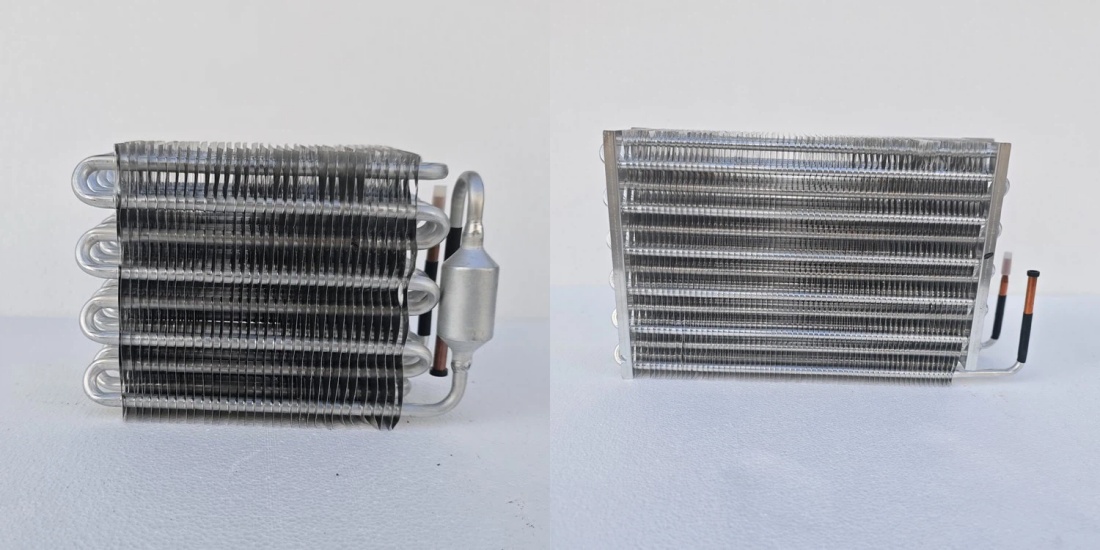

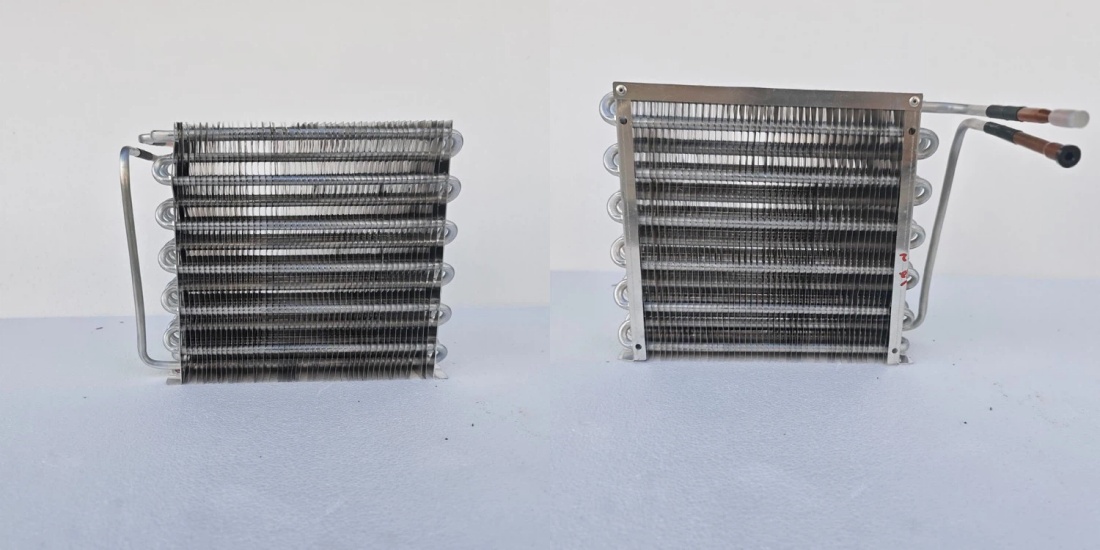

Automobile evaporators

Structure and Design

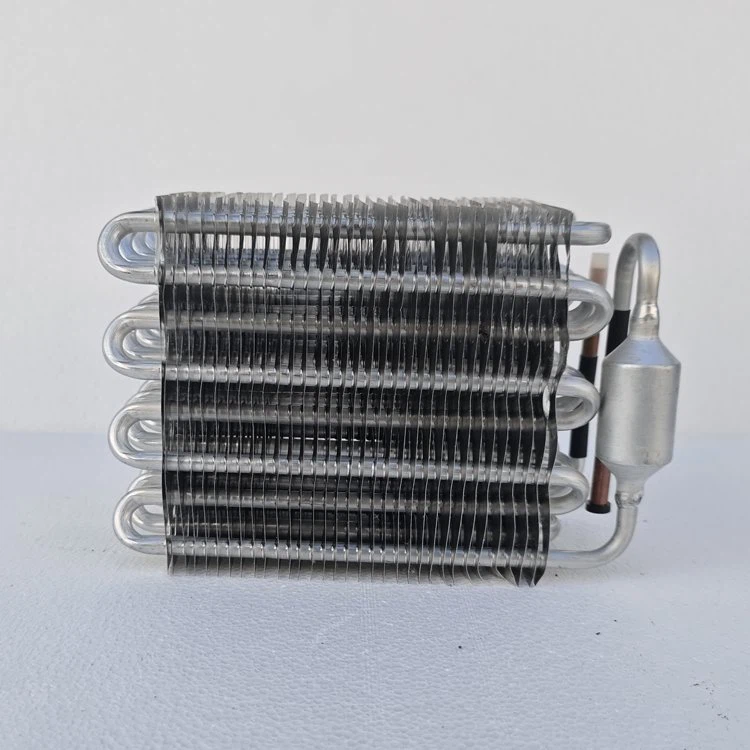

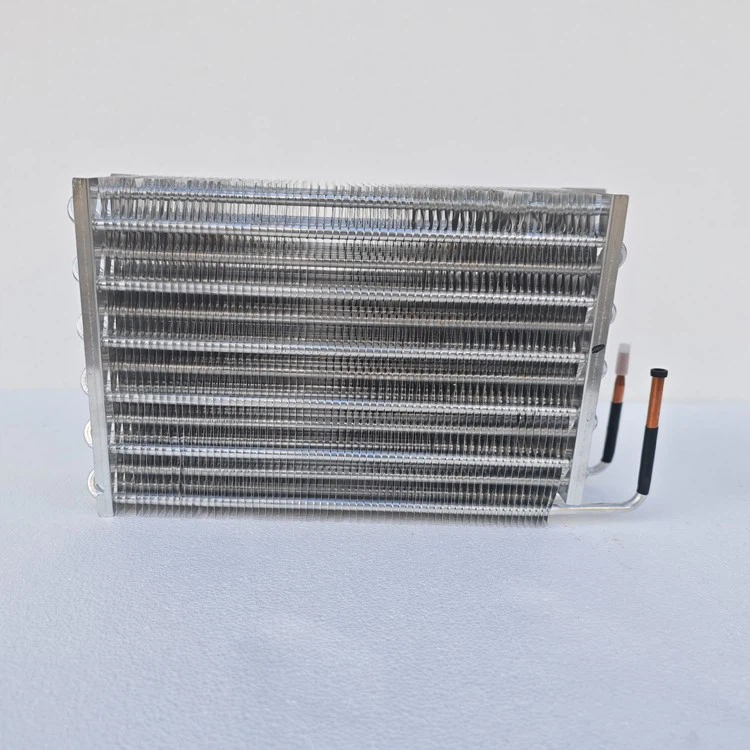

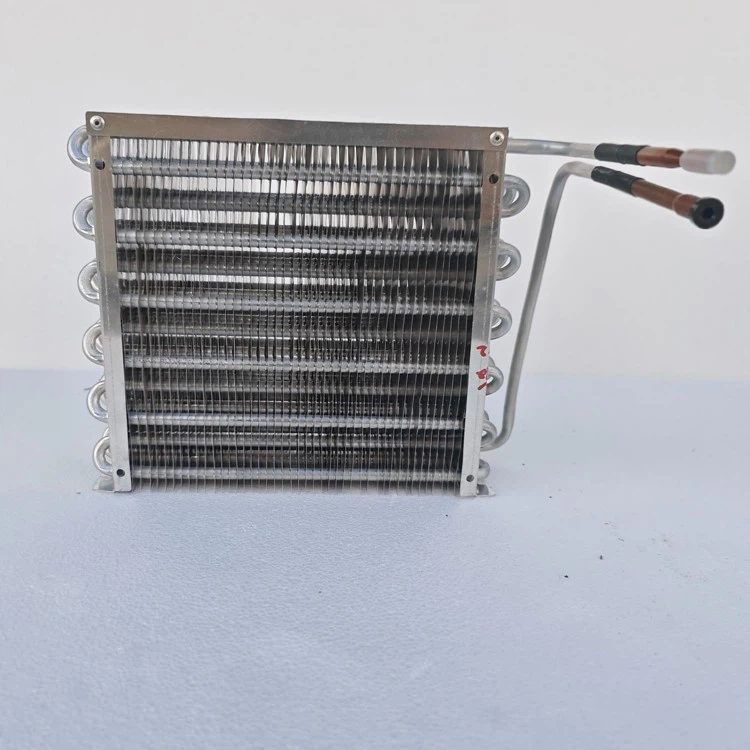

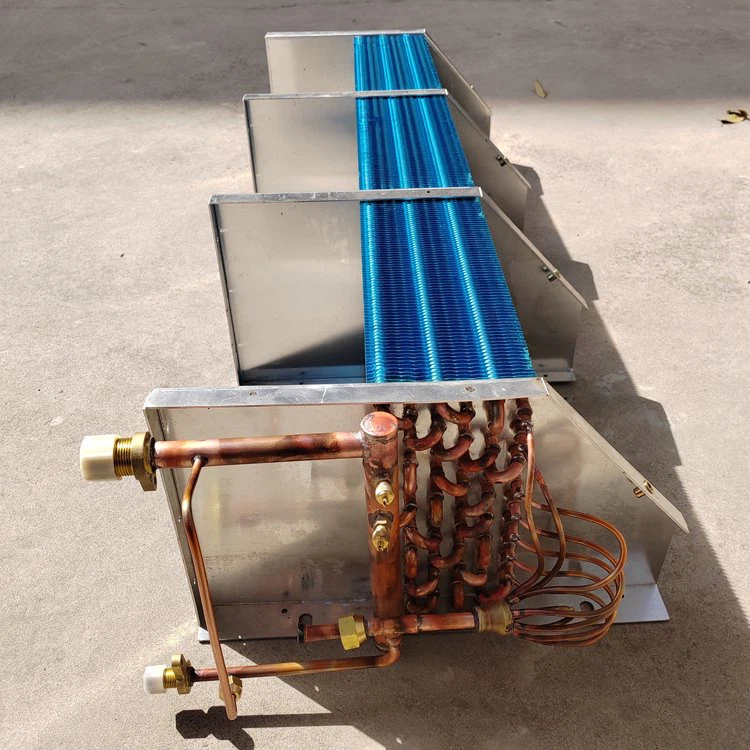

Automobile evaporators are commonly constructed with a series of intricately arranged tubes and fins. The refrigerant circulates through the tubes, while a fan directs air over the fins. This meticulous design maximizes heat transfer efficiency, guaranteeing that the vehicular air is adequately chilled.

The choice of materials for the evaporator is paramount to its performance. Premium materials like aluminum and copper alloys are preferred due to their exceptional corrosion resistance and thermal conductivity.

Operating Principle

Upon entering the evaporator through an expansion valve or orifice tube, the refrigerant liquid undergoes a sudden pressure drop, causing it to expand and cool. As it flows through the evaporator tubes, the refrigerant absorbs heat from the surrounding air, leading to its evaporation and transition into a gas. This process cools the air flowing over the fins. The chilled air is then circulated into the vehicle’s interior, offering a comfortable environment for passengers.

Performance Characteristics

- Efficient Cooling: The evaporator’s design and material choice ensure rapid and effective heat transfer, facilitating swift air cooling.

- Durability: High-quality materials and sturdy construction underpin its long-lasting performance and reliability.

- Compatibility: Automobile evaporators are designed to seamlessly integrate with various automotive air conditioning systems, ensuring broad applicability and straightforward installation.

Maintenance and Care

- Regular Inspection: Conducting periodic inspections for signs of corrosion, clogging, or leakage is crucial. This ensures the evaporator remains in optimal working condition and maintains efficient cooling.

- Cleaning: Keeping the evaporator clean and debris-free enhances its heat transfer efficiency and prolongs its lifespan. Regular cleaning should be an integral part of routine vehicle maintenance.

Application Fields

Automobile evaporators are ubiquitous in various types of vehicles, including cars, trucks, buses, and SUVs. They serve as a fundamental component in automotive air conditioning systems, delivering comfort and convenience to both drivers and passengers alike.

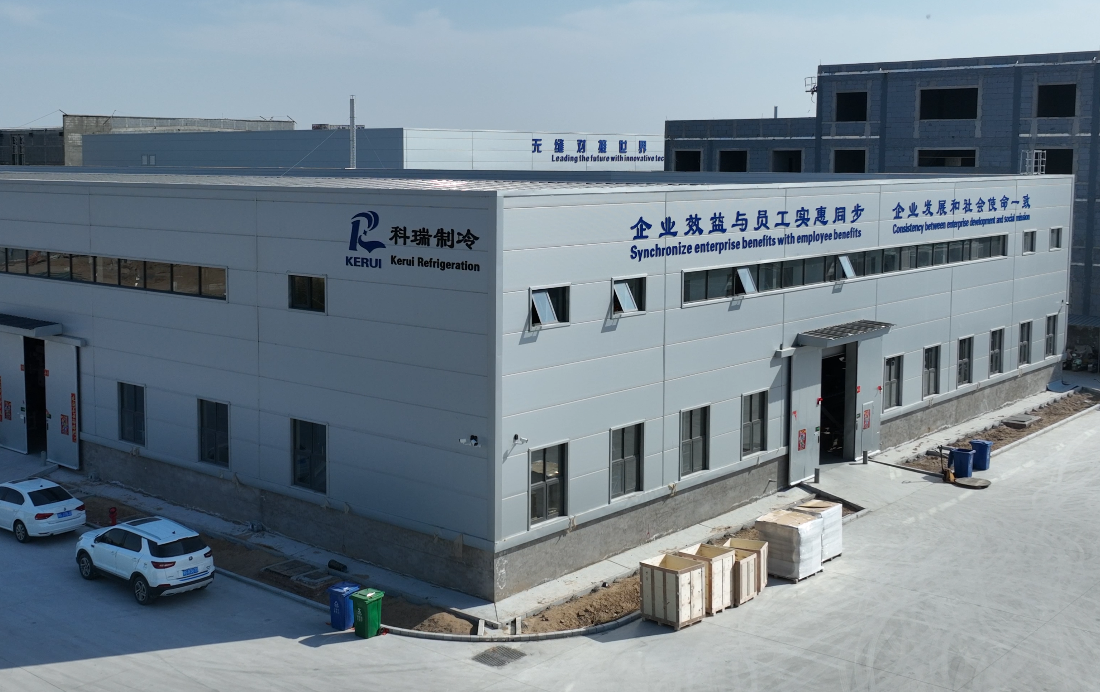

Our Factory

Xinxiang Kerui Electronics Co., Ltd. is a professional enterprise specializing in the production of evaporator and condenser for refrigerator& freezer. The main products of our company are aluminum tube fin evaporator, copper tube fin evaporator, wire on tube evaporator& condenser, micro-channel heater exchanger, tube on plate evaporator. Also, all products raw materials, such as Aluminum coil/foil/sheet, Aluminum tube, copper tube, steel wire, copper-aluminum pipe joints, accumulator, freezer fittings and air conditioner connecting pipe fittings, filters and related products. We own good production equipment, strong technical force, experienced engineering and technical personnel, complete testing facilities, strict product quality guarantee system.

Our company has independent research and development ability, and can develop, trial-produce and mass produce new products according to the requirements of users with high efficiency, professional technology and good service. Our company has advantage in facilities compared with same industry.

The company has always been “efficient management, good quality service, good reputation” integrity for the society, and strive to create cutting-edge management concept, harmonious enterprise atmosphere, to create “Kerui” brand, to create a high starting point, high standard of modern enterprise, to accelerate the regional economic development to make a positive contribution.

We sincerely welcome people from all fields & develop business relationships, explore ways of cooperation, and seek common development!

FAQ

Q1:What color does the product usually make?

A1:Blue gold silver white

Q2:Do you provide OEM or ODM service?

A2:Of course, we can modify the products to satisfy customer’s personalized requirements or work together with customer to design and produce a totally new product.

Q3:How long is the production lead time?

A3:Generally speaking, our production cycle is 15 days. If there is an urgent need, we can negotiate to accelerate the progress.

Q4:How do you make our business long-term and good relationship?

A4: We keep good quality and competitive price to ensure our customers benefit, we respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.