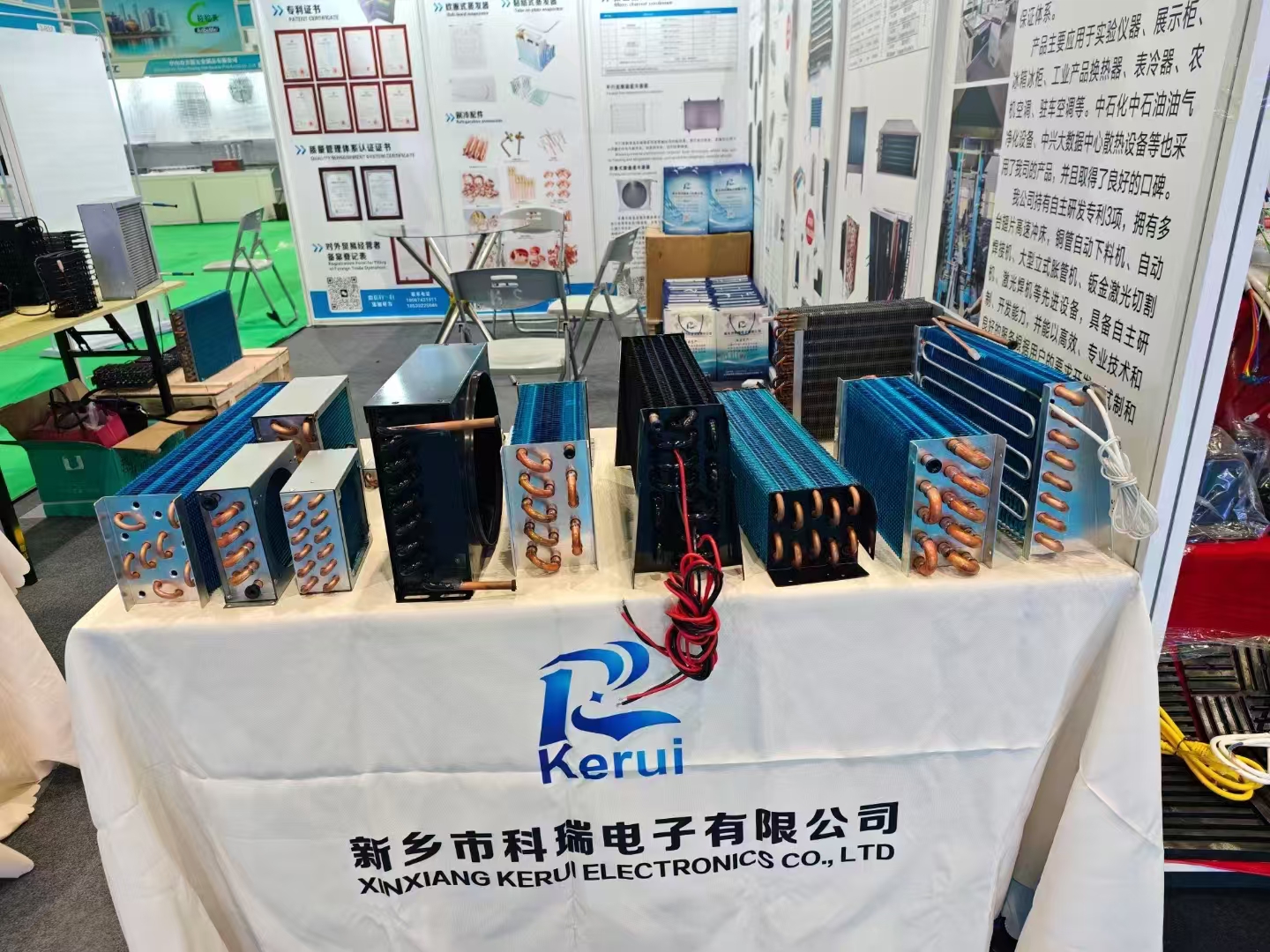

Bus Ac Condenser And Evaporator Coil

Core Functions

- Condenser: Cools and liquefies high-temperature, high-pressure refrigerant, expelling heat outside the vehicle to ensure efficient system operation.

- Evaporator: Absorbs heat from the cabin through refrigerant evaporation, lowering air temperature and providing a comfortable environment.

- Air Circulation: Ensures even distribution of cool air, preventing temperature fluctuations and enhancing passenger comfort.

Key Features

- High Efficiency: Utilizes high thermal conductivity materials (e.g., copper tubes with aluminum fins) for enhanced heat exchange performance and rapid cooling.

- Corrosion Resistance: Features anti-corrosion treatment, suitable for harsh environments like high humidity and salt spray, extending service life.

- Compact Design: Space-saving structure for easy installation and maintenance, ideal for the limited space in buses.

- Energy Efficiency: Optimized design reduces energy consumption and supports eco-friendly refrigerants (e.g., R134a, R407C), complying with international environmental standards.

- Low Noise Operation: Advanced fan design and vibration reduction technology minimize operational noise, improving passenger experience.

Technical Specifications

- Material: Copper tubes with aluminum fins / Stainless steel

- Refrigerant Type: R134a, R407C, R22, etc.

- Operating Temperature Range: -20°C to +60°C

- Compatible Equipment: Bus air conditioning systems

- Airflow: Customized for different bus models to ensure efficient air circulation

- Pressure Resistance: Withstands high-pressure refrigerant, ensuring system safety

Applications

- City Buses: Urban transit buses, BRT systems, suitable for frequent stops and high-load operation.

- Long-Distance Coaches: Intercity buses, tour buses, ideal for long-duration operation and complex road conditions.

- Special Vehicles: School buses, airport shuttles, etc., meeting the unique needs of specialized vehicles.

Customer Value

- Enhanced Passenger Comfort: Rapid cooling and even air distribution ensure a comfortable cabin environment.

- Reduced Operating Costs: Energy-efficient design lowers fuel consumption and electricity costs.

- Extended Equipment Life: Corrosion-resistant materials and optimized design reduce failure rates and maintenance costs.

- Adaptability to Various Environments: Stable performance in high temperatures, humidity, and salt spray conditions.

Installation & Maintenance

- Installation: Customized installation solutions ensure perfect compatibility with bus air conditioning systems, reducing installation time and costs.

- Maintenance: Modular design facilitates easy cleaning and maintenance. Regular checks of refrigerant levels and system leaks ensure long-term reliability.

- After-Sales Service: Professional technical support and responsive after-sales service to address customer concerns.

Previous

Fan Coil Heat Exchanger