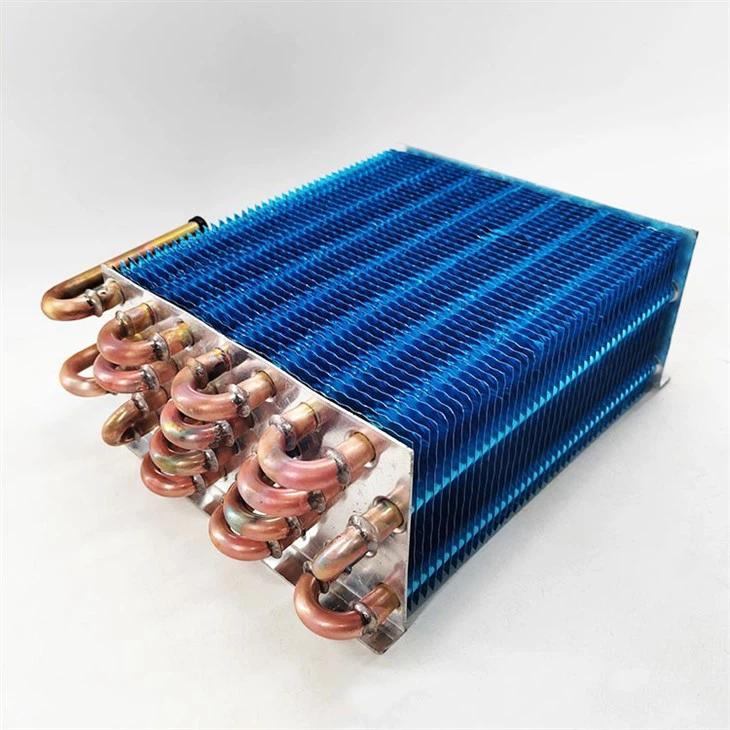

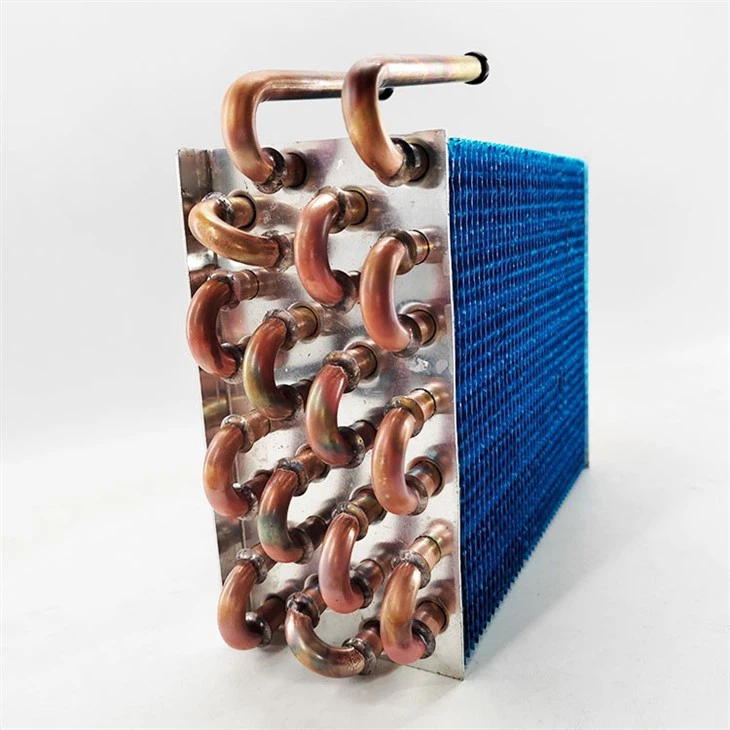

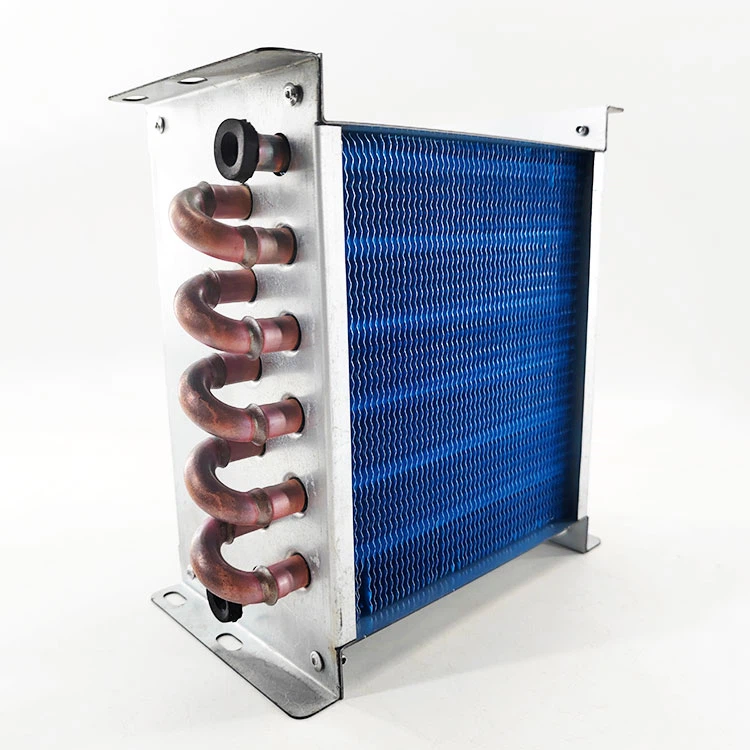

Copper Tube Aluminum Fin Condenser

The production process for copper tube aluminum fin condensers typically involves the following steps:

1. Tube Cutting: Copper tubes of required length are cut from coils.

2. Tube Expansion: The ends of the copper tubes are expanded to ensure a tight fit into the aluminum fins.

3. Finning: The copper tubes are then inserted into the aluminum fins which are rolled onto the tube surface.

4. Core Assembly: The copper tube aluminum fin cores are then assembled by stacking them into a frame and spacing them appropriately.

5. Brazing: The assembled cores are then brazed in a furnace at high temperature to create a solid, leak-proof joint between the copper tubes and aluminum fins.

6. Cleaning: The brazed cores are then cleaned to remove any residue or impurities left from the brazing process.

7. Painting: The condenser is painted with a corrosion-resistant coating to protect it from the elements.

8. Final Assembly: Other components, such as fans, are then attached to the finished condenser to create a complete unit.

Once the condenser is assembled and tested, it is ready to be installed in a variety of air conditioning and refrigeration applications.

Product display:

Certificate of honor

Other different types of evaporator/condenser

Product superiority

Factory actual shoot

Service process

Packaging transportation