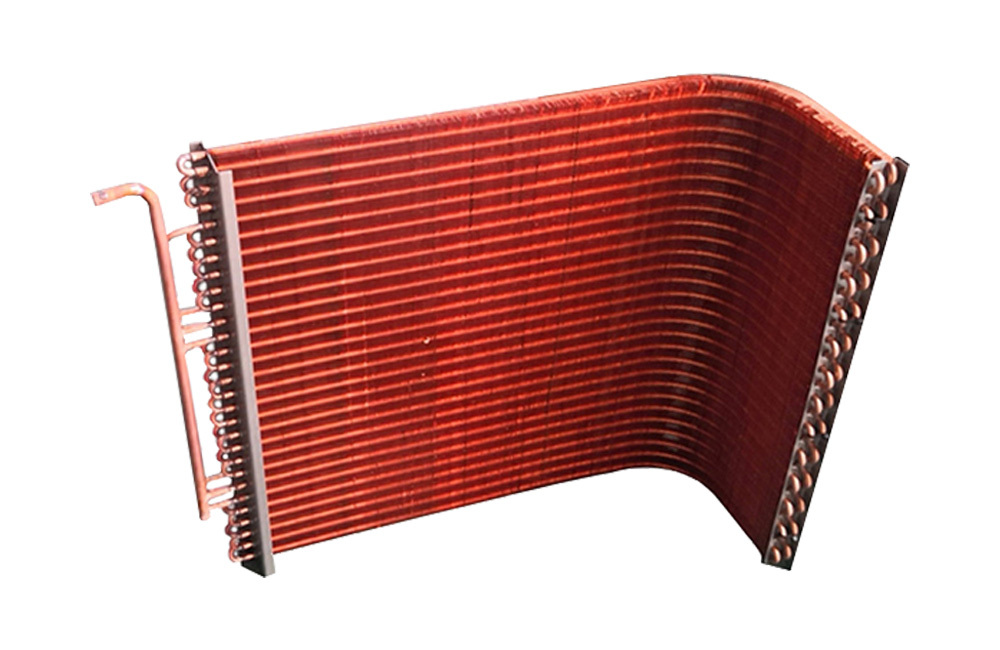

Copper Tube Copper Fin Heat Exchanger

Core Functions

- Efficient Heat Exchange: The high thermal conductivity of copper tubes and fins ensures rapid and efficient heat transfer.

- Corrosion Resistance: Copper’s natural resistance to corrosion makes it suitable for various environments, extending equipment life.

- Wide Application: Suitable for air conditioning, refrigeration, and industrial heating and cooling systems.

Key Features

- High Thermal Conductivity: The combination of copper tubes and fins provides superior heat transfer efficiency.

- Corrosion Resistance: Copper resists corrosion from various chemicals, making it ideal for harsh environments.

- Compact Design: Space-saving structure for easy installation and maintenance.

- Long Lifespan: High-quality copper materials ensure long-term reliability and reduced maintenance needs.

Technical Specifications

- Material: Copper tubes and fins

- Operating Temperature Range: -50°C to +200°C

- Compatible Media: Air, water, refrigerants, etc.

- Applications: Air conditioning, refrigeration, industrial heating and cooling systems

Applications

- Air Conditioning Systems: Residential, commercial, and industrial air conditioning systems.

- Refrigeration Equipment: Refrigerators, freezers, chillers, etc.

- Industrial Heating and Cooling: Heating and cooling systems in chemical, petroleum, and power industries.

Customer Value

- Energy Efficiency: Superior heat transfer efficiency reduces energy consumption and operational costs.

- Reliability and Durability: Corrosion resistance and high-quality materials ensure long-term stable operation.

- Easy Maintenance: Simplified maintenance processes reduce downtime.

Installation & Maintenance

- Installation: Detailed installation guidelines and professional technical support ensure proper setup and operation.

- Maintenance: Regular cleaning of fins and system checks ensure efficient operation and long lifespan.