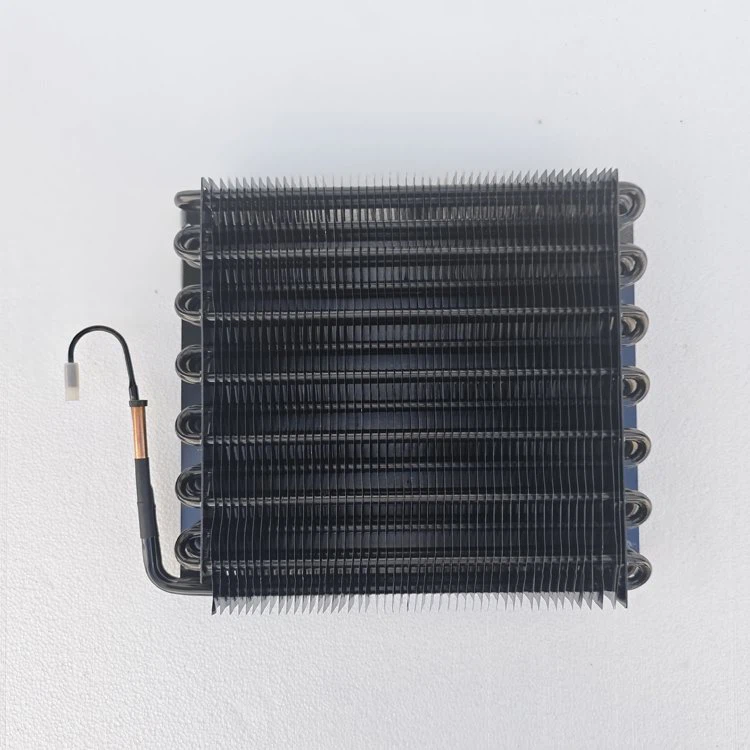

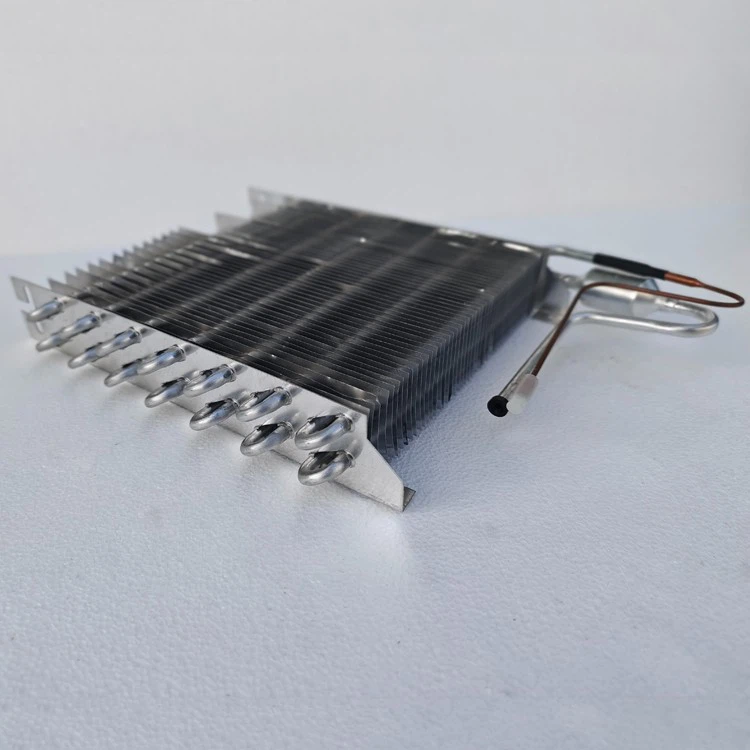

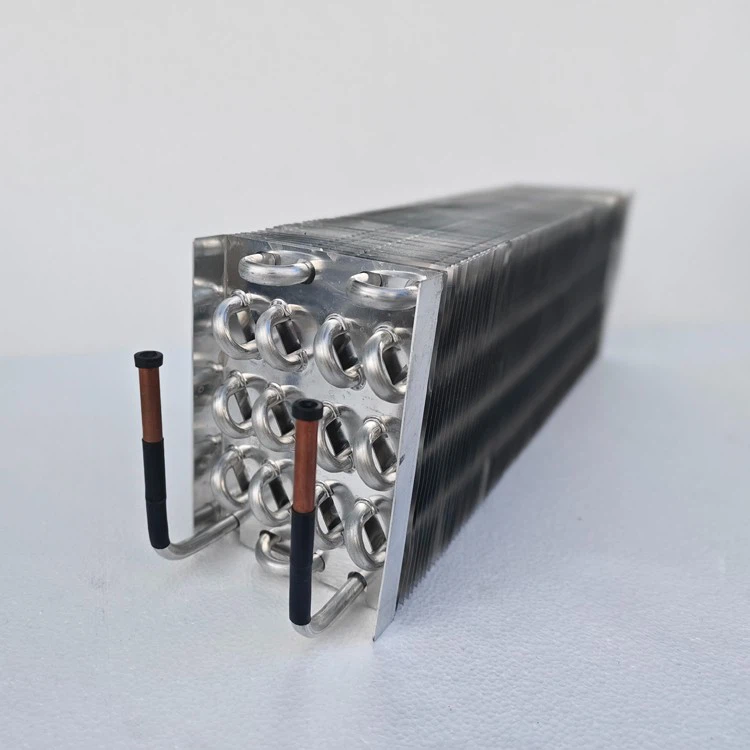

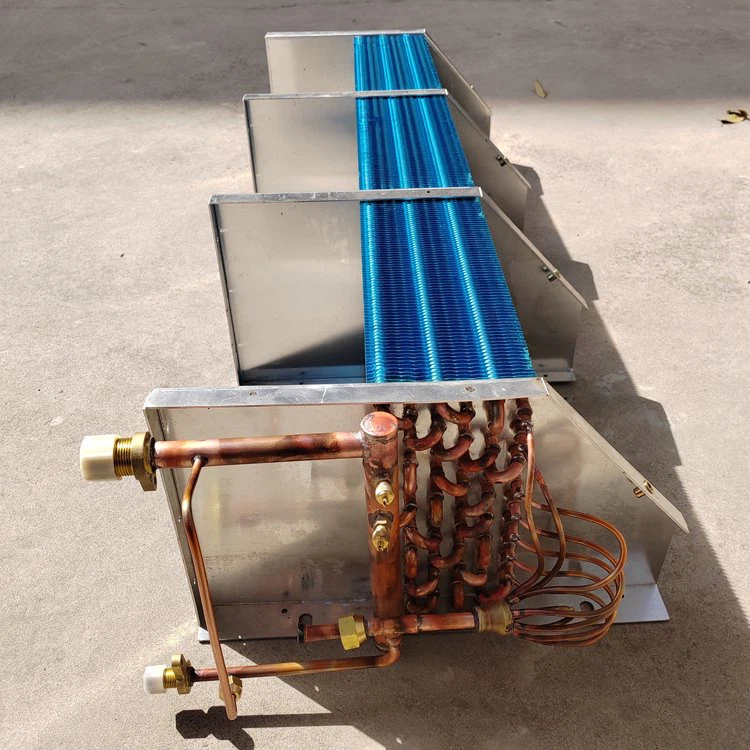

Electrophoretic Anti-corrosion Aluminum Tube Aluminum Fin Evaporator

The evaporator is mainly composed of aluminum tubes, aluminum foil fins, connectors and sealing materials. Among them, aluminum tubes and aluminum foil fins are the main heat exchange elements, and the finned tube structure is formed by specific manufacturing processes (such as aluminum foil punching, aluminum tube bending, tube expansion, welding, etc.), which greatly increases the heat exchange area and improves the heat exchange efficiency.

Manufacturing process

The manufacturing process of aluminum fin tube evaporator is relatively complex, including aluminum foil punching, aluminum tube bending, tube expanding, cleaning, welding, leakage testing, drying, surface treatment, nitrogen flushing and packaging. These steps ensure that the quality and performance of the evaporator meet the design requirements.

|

|

Width(mm) |

Thickness(mm) |

Hole No. |

|

Flat pipe specifications |

12 | 1.2 | 17 |

| 16 | 1.3 | 16 | |

| 20 | 2 | 12 | |

| 25.4 | 2 | 13 | |

| 25.4 | 2 | 20 | |

| 32 | 2 | 25 | |

| 36 | 2 | 26 | |

| 36 | 3 | 23 | |

|

|

|||

|

fin |

plain |

||

|

corrugated plate |

|||

|

window plate |

|||

- Clean fins and pipes: Regularly clean dirt and dust from the surface of fins and pipes to keep them clean and unblocked.

- Check the joints: Check the tightness and stability of the joints regularly to ensure that there is no leakage and loosening.

- Replace worn parts: Replace badly worn parts, such as seals and connectors, in time to ensure normal operation of the device.