Epoxy Resin Fin Heat Exchanger

The Epoxy Resin Fin Heat Exchanger stands out for its exceptional corrosion resistance, thanks to the epoxy resin-coated fins that withstand harsh chemicals like acids, alkalis, and salts. Its high thermal efficiency, achieved through an optimized fin design, ensures superior heat transfer performance in both high and low-temperature environments. The lightweight construction simplifies installation and reduces maintenance efforts, while the customizable design allows it to meet specific operational needs. With a long service life and low maintenance costs, this heat exchanger is a cost-effective and reliable solution for industries dealing with corrosive media. Additionally, it is environmentally friendly, minimizing leakage risks and complying with industry standards. Supported by comprehensive after-sales services, it ensures seamless operation and peace of mind.

Product Structure

-

Fins: Made of high thermal conductivity materials (such as aluminum or copper) with an epoxy resin coating for enhanced corrosion resistance.

-

Tube Bundle: Typically constructed from stainless steel or other corrosion-resistant materials for fluid flow.

-

Casing: Protects the internal structure, usually made of corrosion-resistant materials or coated for durability.

Applications

-

Chemical Industry: Used for cooling or heating corrosive gases or liquids.

-

Power Industry: Suitable for waste heat recovery, flue gas desulfurization, and denitrification systems.

-

Metallurgical Industry: Used in high-temperature flue gas treatment or cooling systems.

-

Pharmaceutical Industry: Ideal for heat exchange processes involving corrosive media.

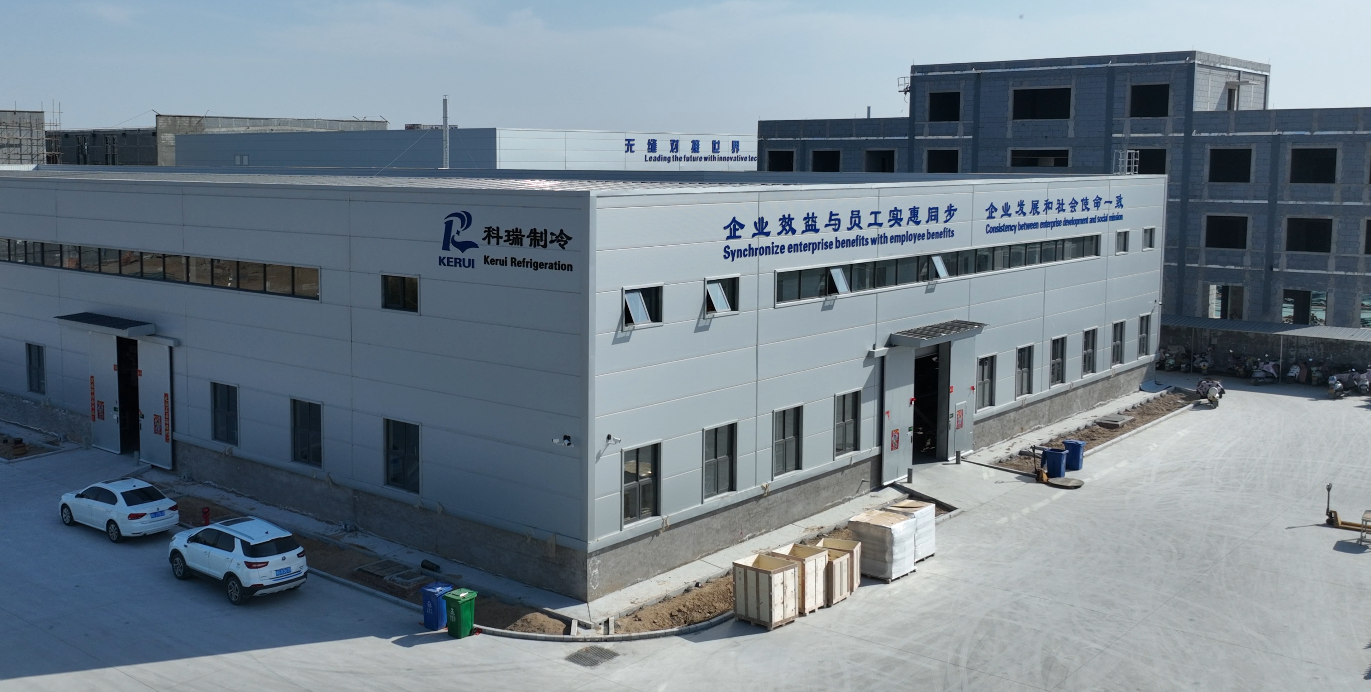

Our Factory

Xinxiang Kerui Electronics Co., Ltd. is a professional enterprise specializing in the production of evaporator and condenser for refrigerator& freezer .The main products of our company are aluminum tube fin evaporator, copper tube fin evaporator, wire on tube evaporator& condenser,micro-channel heater exchanger,tube on plate evaporator. Also all products raw materials ,such as Aluminum coil/foil/sheet,Aluminum tube, copper tube,steel wire, copper-aluminum pipe joints ,accumulator,freezer fittings and air conditioner connecting pipe fittings, filters and related products.We own good production equipment, strong technical force, experienced engineering and technical personnel, complete testing facilities, strict product quality guarantee system.

Our company has independent research and development ability, and can develop, trial-produce and mass produce new products according to the requirements of users with high efficiency, professional technology and good service. Our company has advantage in facilities compared with same industry.

The company has always been “efficient management, good quality service, good reputation” integrity for the society, and strive to create cutting-edge management concept, harmonious enterprise atmosphere, to create “Kerui” brand, to create a high starting point, high standard of modern enterprise, to accelerate the regional economic development to make a positive contribution.

We sincerely welcome people from all fields & develop business relationships, explore ways of cooperation, and seek common development!