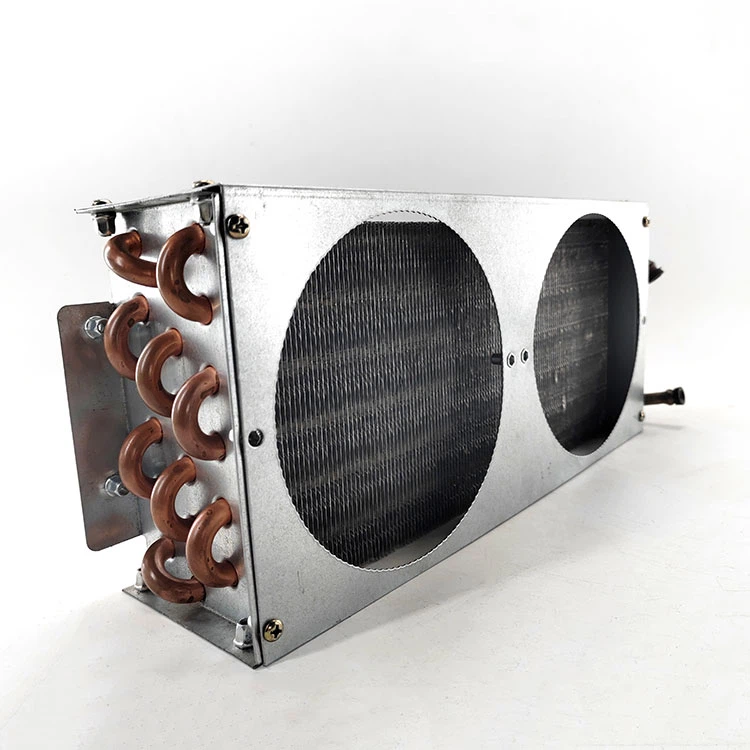

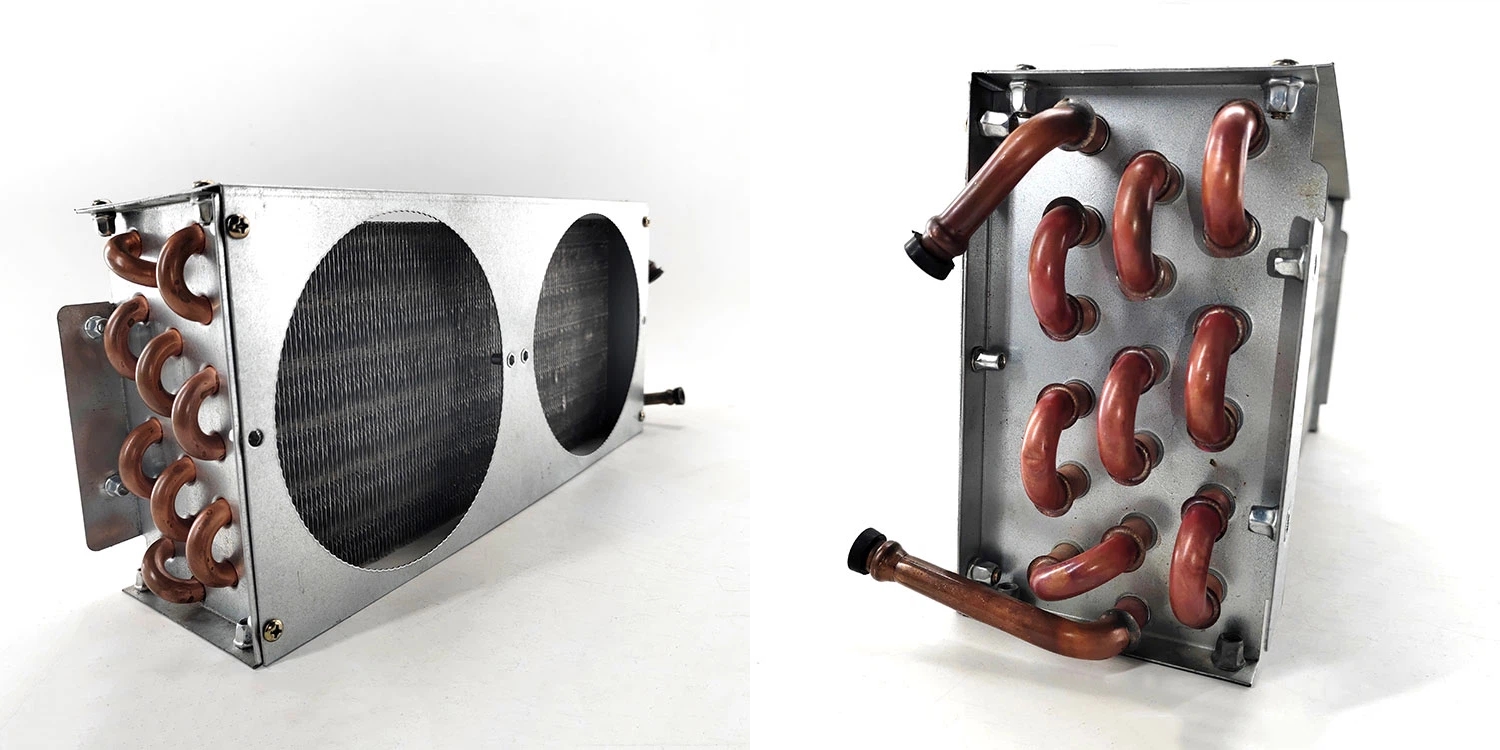

Fin Heat Exchanger

1. Product Overview

The Fin Heat Exchanger stands out as a highly efficient heat exchange device primarily used in HVAC, refrigeration, and industrial systems. It facilitates heat exchange between air and fluids (such as water, steam, or refrigerant) to achieve heating or cooling functions. Its core design consists of fins and tubes, with the fins increasing the heat exchange surface area and significantly boosting thermal conductivity efficiency. This product is applicable in various environments and scenarios, including commercial, industrial, and residential sectors.

2. Key Features

- Efficient Heat Exchange: The fin design significantly increases the heat exchange surface area, enhancing thermal conductivity.

- Compact Structure: Its small size makes it ideal for installation in equipment with limited space.

- Durable Materials: High-quality copper tubes and aluminum fins offer excellent corrosion resistance and thermal conductivity.

- Broad Compatibility: Suitable for various media including water, steam, and refrigerant.

- Low Maintenance: Simple design facilitates easy cleaning and maintenance.

- Customization Options: Available in various sizes, fin densities, and configurations to meet specific needs.

3. Technical Specifications

- Materials: Copper tubes (standard) or steel tubes (optional); Aluminum fins (standard) or coated fins.

- Fin Density: Adjustable (typically 8-16 fins per inch).

- Tube Diameter: Customizable (common sizes: 3/8″, 1/2″, 5/8″).

- Working Pressure: Designed for high-pressure environments, ensuring safety and reliability.

- Temperature Range: Suitable for temperatures from -20°C to 120°C.

- Certifications: Compliant with ISO, CE, AHRI, and other industry standards.

4. Application Areas

- HVAC Systems: Central air conditioning, air handling units.

- Refrigeration Systems: Chillers, cold storage facilities.

- Industrial Heating & Cooling: Process heating, waste heat recovery, fluid cooling.

- Special Applications: Laboratories, hospitals, clean rooms, and other places requiring precise temperature control.

5. Product Advantages

- Energy Efficiency: Optimizes heat exchange performance, reducing energy consumption.

- Extended Lifespan: Durable materials and robust structure ensure long-term stable operation.

- Low Noise: Design optimizations reduce operational noise.

- Environmentally Friendly: Efficient heat exchange minimizes energy waste, supporting sustainable development.

6. Ordering Information

- Please contact our sales team for pricing, delivery times, and customization options. Provide details such as system type, media (water, steam, refrigerant), size, and any special requirements for a tailored solution.

7. Support & Warranty

- Comprehensive technical support, including installation guidance and troubleshooting.

- Standard warranty service with options to extend the warranty period based on needs.

Product superiority

Factory actual shoot

Service process

Packaging transportation