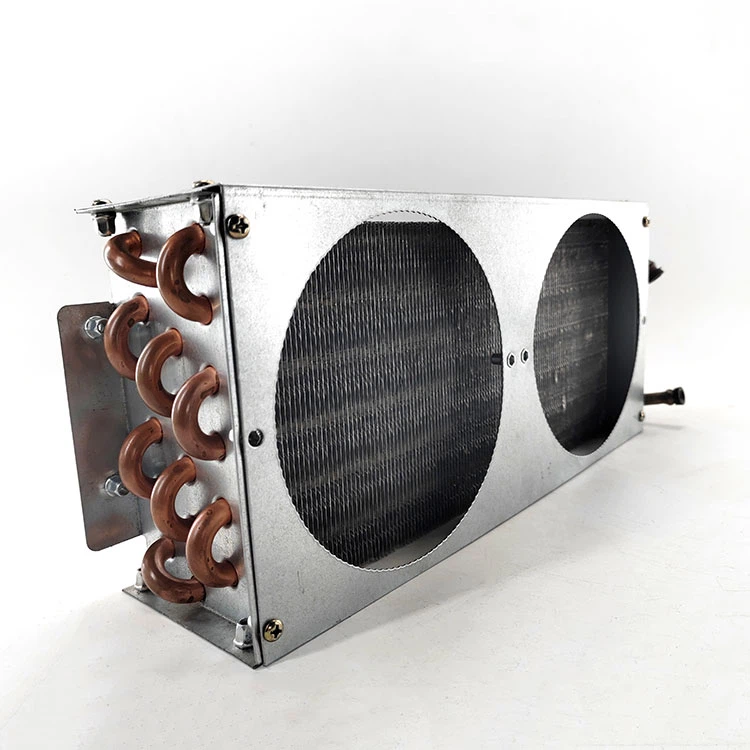

Heat exchanger for laser machine

Core Functions

- Heat Dissipation: Absorbs and transfers heat generated by laser equipment using liquid or gas cooling media.

- Temperature Control: Maintains a constant temperature for laser sources and critical components, ensuring stable operation.

- Equipment Protection: Prevents performance degradation or component damage caused by overheating.

Key Features

- High Efficiency: Utilizes high thermal conductivity materials (e.g., copper, aluminum, or stainless steel) to enhance heat exchange performance.

- Corrosion Resistance: Compatible with various cooling media (e.g., water, glycol solutions) and offers strong anti-corrosion properties.

- Compact Design: Space-saving structure for easy integration into laser equipment.

- High Reliability: Rigorously tested to ensure stability under prolonged high-load operation.

Technical Specifications

- Material: Copper, Aluminum, Stainless steel

- Cooling Media: Water, Glycol solutions, Air

- Operating Temperature Range: -10°C to +80°C

- Compatible Laser Equipment: CO2 lasers, Fiber lasers, UV lasers, etc.

Applications

- Industrial Laser Processing: Metal cutting, welding, marking, etc.

- Medical Laser Equipment: Laser surgical devices, cosmetic instruments, etc.

- Scientific Laser Equipment: Laboratory lasers, optical experimental devices, etc.

Installation & Maintenance

- Installation: Must be performed by qualified technicians to ensure compatibility and optimal performance with laser equipment.

- Maintenance: Regularly check cooling media flow and clean the heat exchanger surface to ensure long-term reliability.