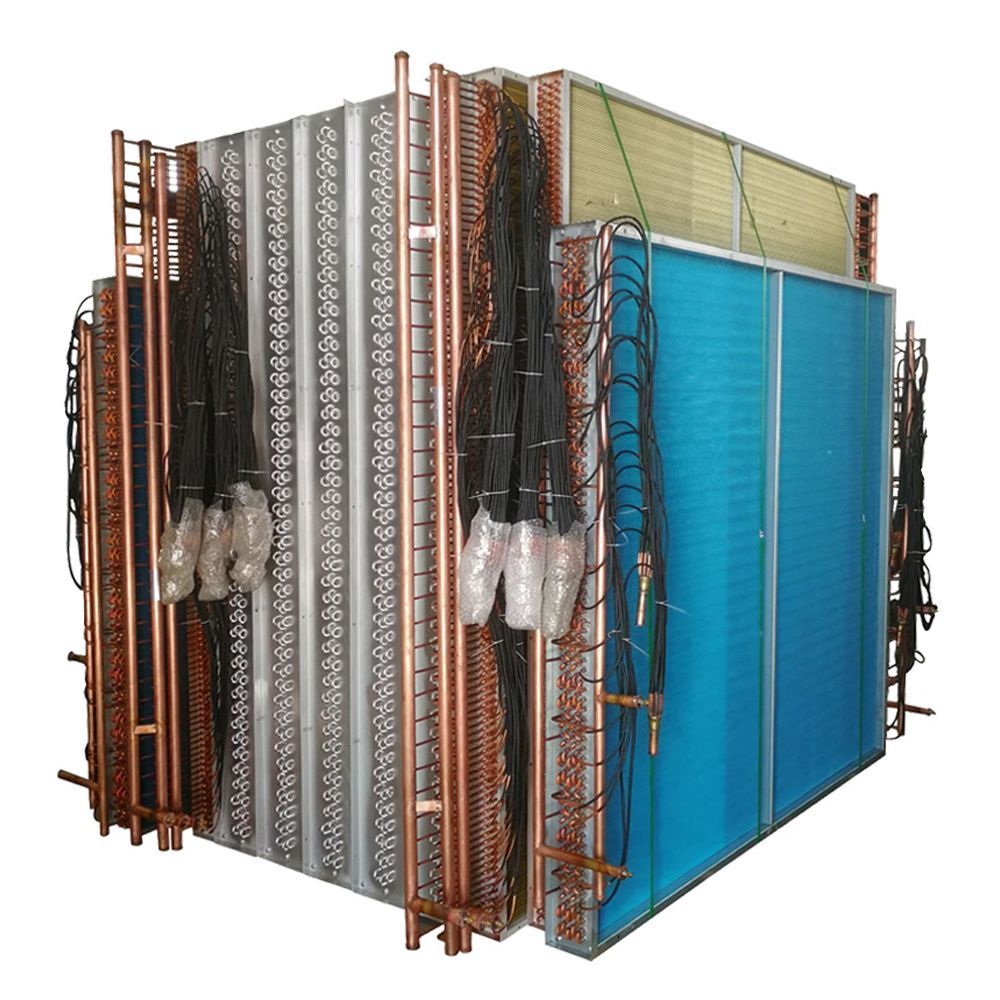

Refrigerant Coil

Core Functions

- Evaporator Coil: Absorbs heat through refrigerant evaporation, lowering air or liquid temperature.

- Condenser Coil: Releases heat through refrigerant condensation, expelling heat from the system.

- Heat Exchange Efficiency: Optimized design ensures efficient heat transfer, enhancing system performance.

Key Features

- High Thermal Conductivity: Utilizes copper tubes with aluminum fins or stainless steel for superior heat exchange efficiency.

- Corrosion Resistance: Features anti-corrosion treatment, suitable for various environmental conditions, extending service life.

- Compact Design: Space-saving structure for easy installation and maintenance.

- Versatility: Compatible with various refrigerants (e.g., R134a, R410A, R22).

Technical Specifications

- Material: Copper tubes with aluminum fins / Stainless steel

- Refrigerant Type: R134a, R410A, R22, etc.

- Operating Temperature Range: -50°C to +150°C

- Compatible Equipment: Air conditioners, refrigeration units, heat pump systems

Applications

- Residential Air Conditioning: Split air conditioners, window air conditioners, etc.

- Commercial Refrigeration: Supermarket display cases, cold storage rooms, chillers, etc.

- Industrial Cooling: Cooling systems in chemical, food processing, and pharmaceutical industries.

Product Benefits

- Energy Efficiency: Optimized design reduces energy consumption and operational costs.

- Reliability and Durability: High-quality materials and corrosion resistance ensure long-term stable operation.

- Easy Maintenance: Modular design simplifies cleaning and maintenance processes, reducing downtime.

Installation & Maintenance

- Installation: Detailed installation guidelines and professional technical support ensure proper setup and operation.

- Maintenance: Regular cleaning of fins and system checks ensure efficient operation and long lifespan.