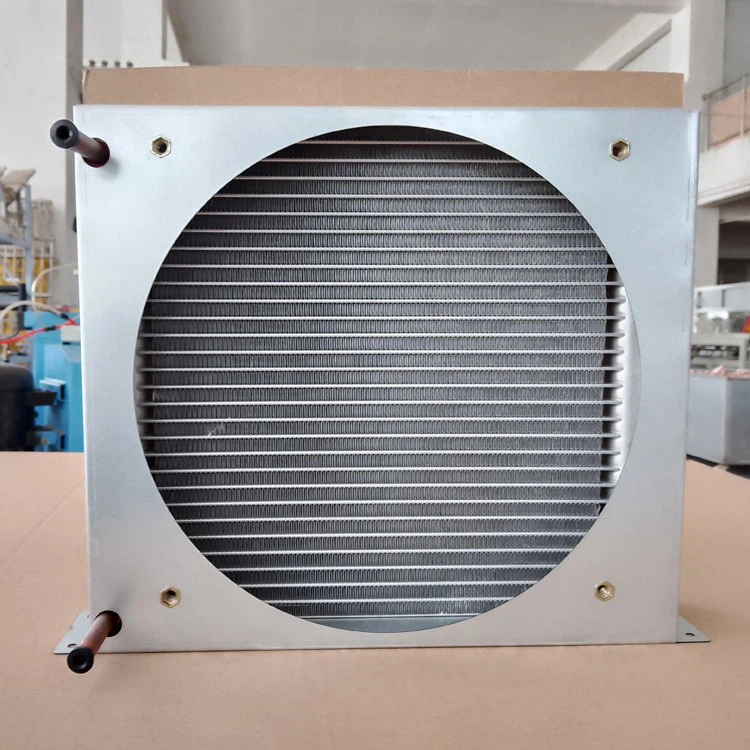

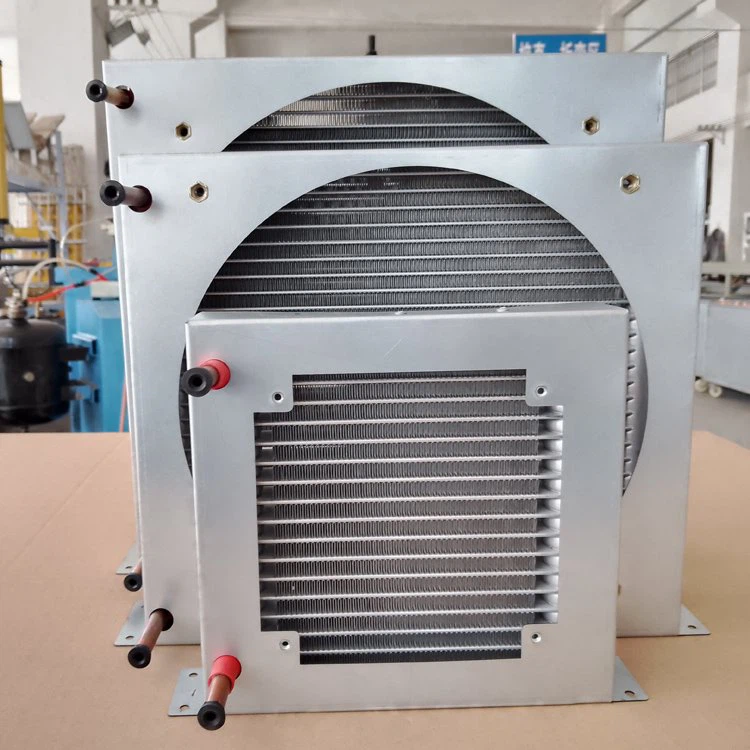

Refrigerator Microchannel Condenser

Structural Characteristics:

-

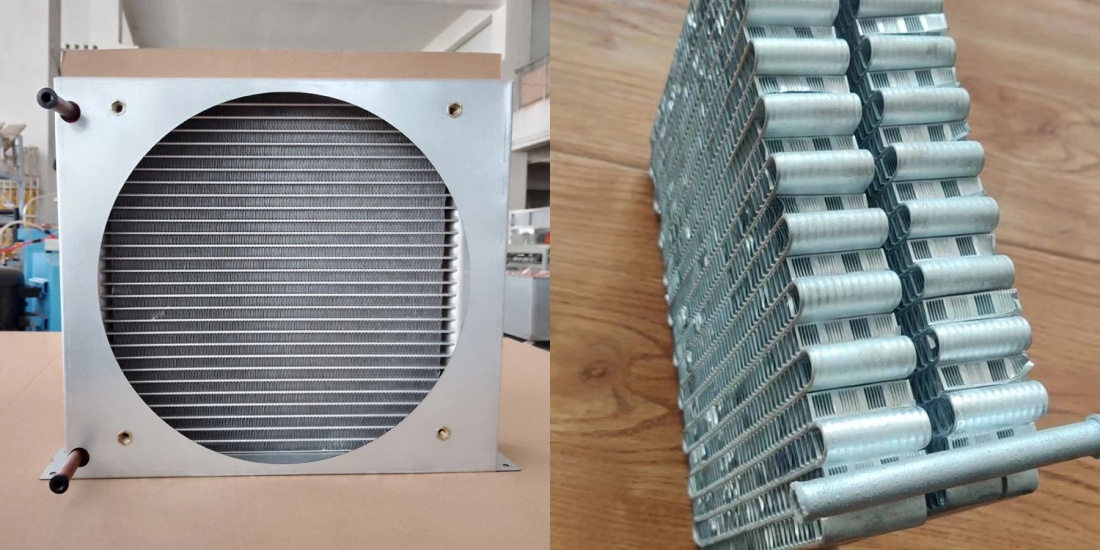

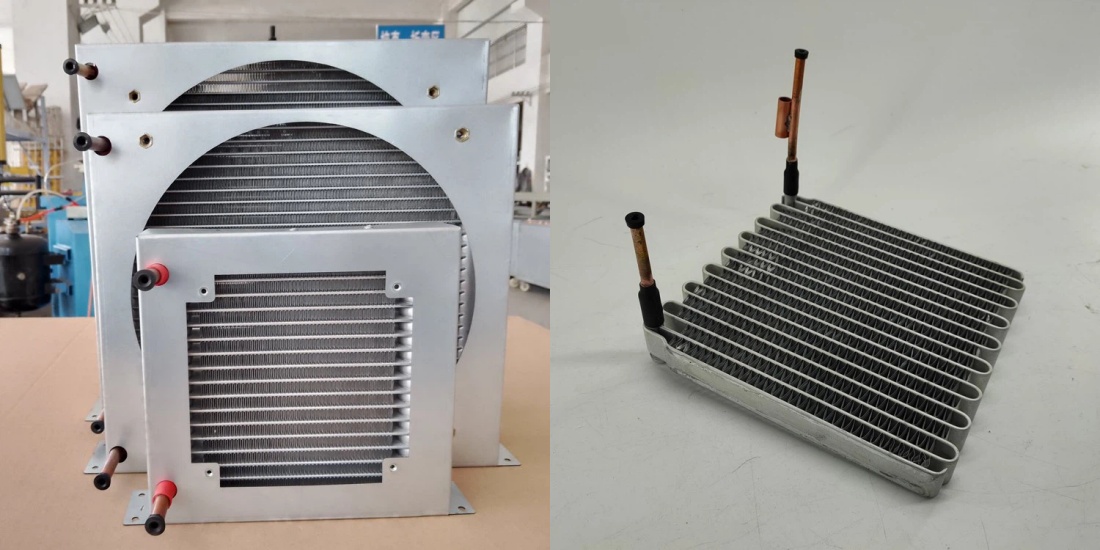

- Microchannel Design: Utilizes a tiny channel structure to increase the heat exchange area and enhance heat exchange efficiency.

- High-Quality Materials: Typically made of high-quality copper or aluminum, exhibiting good thermal conductivity and corrosion resistance.

- Compact Structure: Small size and light weight for easy installation and maintenance.

Performance Characteristics:

-

- Efficient Cooling: The microchannel structure allows for more uniform refrigerant flow in the condenser, improving cooling efficiency.

- Low Energy Consumption: The high heat exchange performance results in lower energy consumption during the refrigerator’s cooling process, making it more energy-efficient and environmentally friendly.

- Fast Cooling Speed: The microchannel condenser can quickly condense refrigerant into a liquid state, accelerating the refrigerator’s cooling speed.

Application Scenarios:

-

- Household Refrigerators: Suitable for various household refrigerator products, improving cooling efficiency and reducing energy consumption.

- Commercial Refrigerators: In commercial settings such as supermarkets and convenience stores, the microchannel condenser similarly demonstrates outstanding cooling performance.

Maintenance and Care:

-

- Regular Cleaning: Keep the condenser surface clean to avoid the accumulation of dust and dirt that can affect heat exchange efficiency.

- Refrigerant Inspection: Regularly check the refrigerant quantity and quality to ensure the refrigerator operates normally.

- Avoid Collision: Prevent the condenser from being bumped or crushed to avoid damaging its structure.

Our Factory

Xinxiang Kerui Electronics Co., Ltd. is a professional enterprise specializing in the production of evaporator and condenser for refrigerator& freezer. The main products of our company are aluminum tube fin evaporator, copper tube fin evaporator, wire on tube evaporator& condenser, micro-channel heater exchanger, tube on plate evaporator. Also, all products raw materials, such as Aluminum coil/foil/sheet, Aluminum tube, copper tube, steel wire, copper-aluminum pipe joints, accumulator, freezer fittings and air conditioner connecting pipe fittings, filters and related products. We own good production equipment, strong technical force, experienced engineering and technical personnel, complete testing facilities, strict product quality guarantee system.

Our company has independent research and development ability, and can develop, trial-produce and mass produce new products according to the requirements of users with high efficiency, professional technology and good service. Our company has advantage in facilities compared with same industry.

The company has always been “efficient management, good quality service, good reputation” integrity for the society, and strive to create cutting-edge management concept, harmonious enterprise atmosphere, to create “Kerui” brand, to create a high starting point, high standard of modern enterprise, to accelerate the regional economic development to make a positive contribution.

We sincerely welcome people from all fields & develop business relationships, explore ways of cooperation, and seek common development!

FAQ

Q1: What color does the product usually make?

A1: Blue gold silver white

Q2: Do you provide OEM or ODM service?

A2: Of course, we can modify the products to satisfy customer’s personalized requirements or work together with customer to design and produce a totally new product.

Q3: How long is the production lead time?

A3: Generally speaking, our production cycle is 15 days. If there is an urgent need, we can negotiate to accelerate the progress.

Q4: How do you make our business long-term and good relationship?

A4: We keep good quality and competitive price to ensure our customers benefit, we respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.