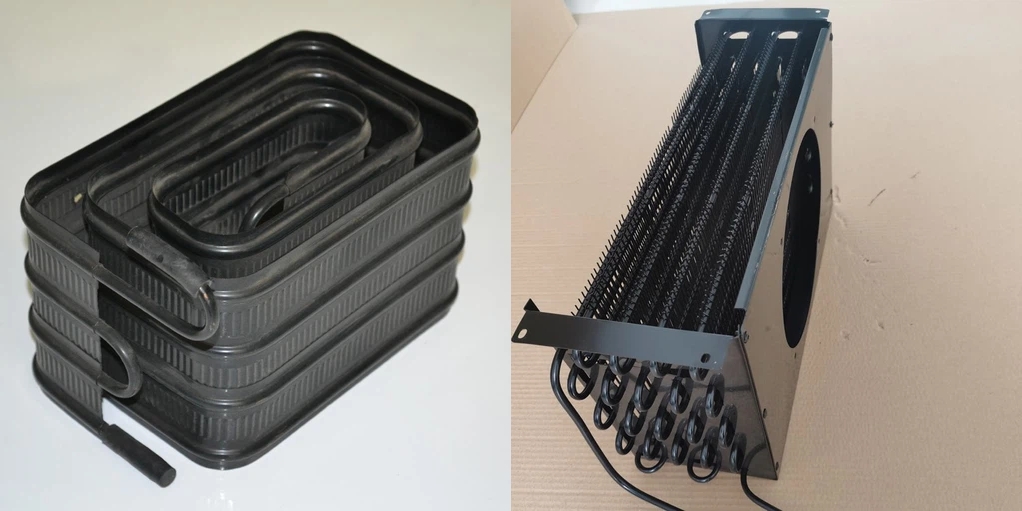

Stainless Steel Condenser

Structure & Material:

-

- Primary Structure: The stainless steel condenser typically consists of shell-and-tube, plate, spiral plate, or other configurations, with the shell-and-tube type being a common variety.

- Material Selection: Constructed from premium stainless steel grades (e.g., SS304, SS316), ensuring corrosion resistance and long-term stability.

Operating Principle:

-

- Gases or vapors flow through the condenser tubes, exchanging heat with the cooling medium (water, air, etc.) outside the tubes.

- During heat exchange, the heat from the gases or vapors is transferred to the cooling medium, causing condensation into a liquid state.

Performance Characteristics:

-

- Efficient Heat Transfer: The stainless steel condenser demonstrates superior heat transfer capabilities, enabling rapid condensation of gases.

- Corrosion Resistance: Made of stainless steel, it resists erosion from various corrosive media, extending equipment lifespan.

- High-Temperature Stability: Capable of withstanding high temperatures and pressures, ensuring system stability.

- Ease of Maintenance: Designed with a reasonable structure, facilitating cleaning and maintenance, reducing operational costs.

Application Fields:

-

- Petrochemical Industry: Widely used in condensing hydrocarbon and other chemical vapors.

- Refrigeration Industry: Acts as a heat-releasing device in refrigeration systems, transferring heat from evaporators to cooling media.

- Other Fields: Also applied in turbine vapor condensation in power plants, refrigeration vapor condensation in freezing plants, and vapor condensation in distillation processes.

Selection & Customization:

-

- Selection Advice: When selecting a stainless steel condenser, consider the system’s refrigerating capacity, working pressure, operating temperature, and cooling medium.

- Customization Services: Offers customized services, designing and manufacturing according to specific client needs, meeting various application requirements.

Previous

Dry Cooling Coil