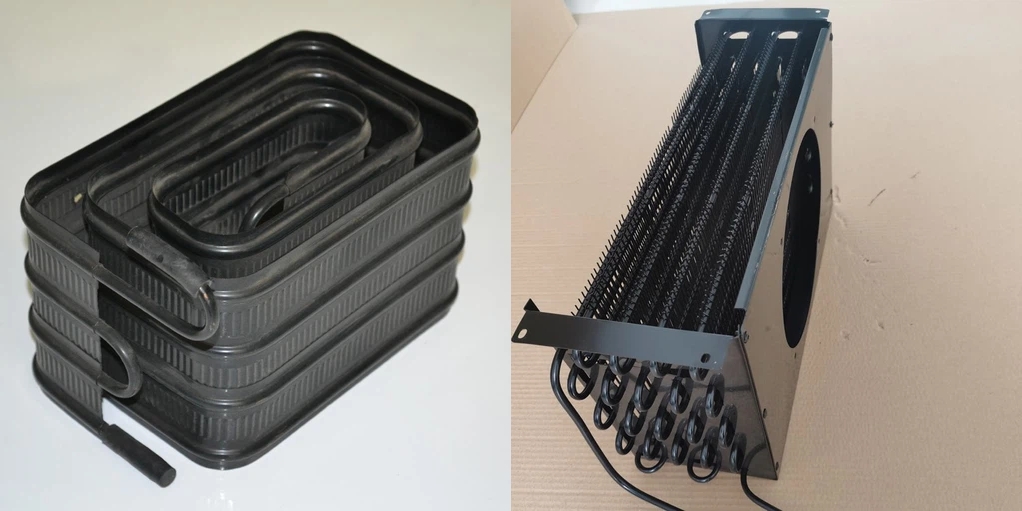

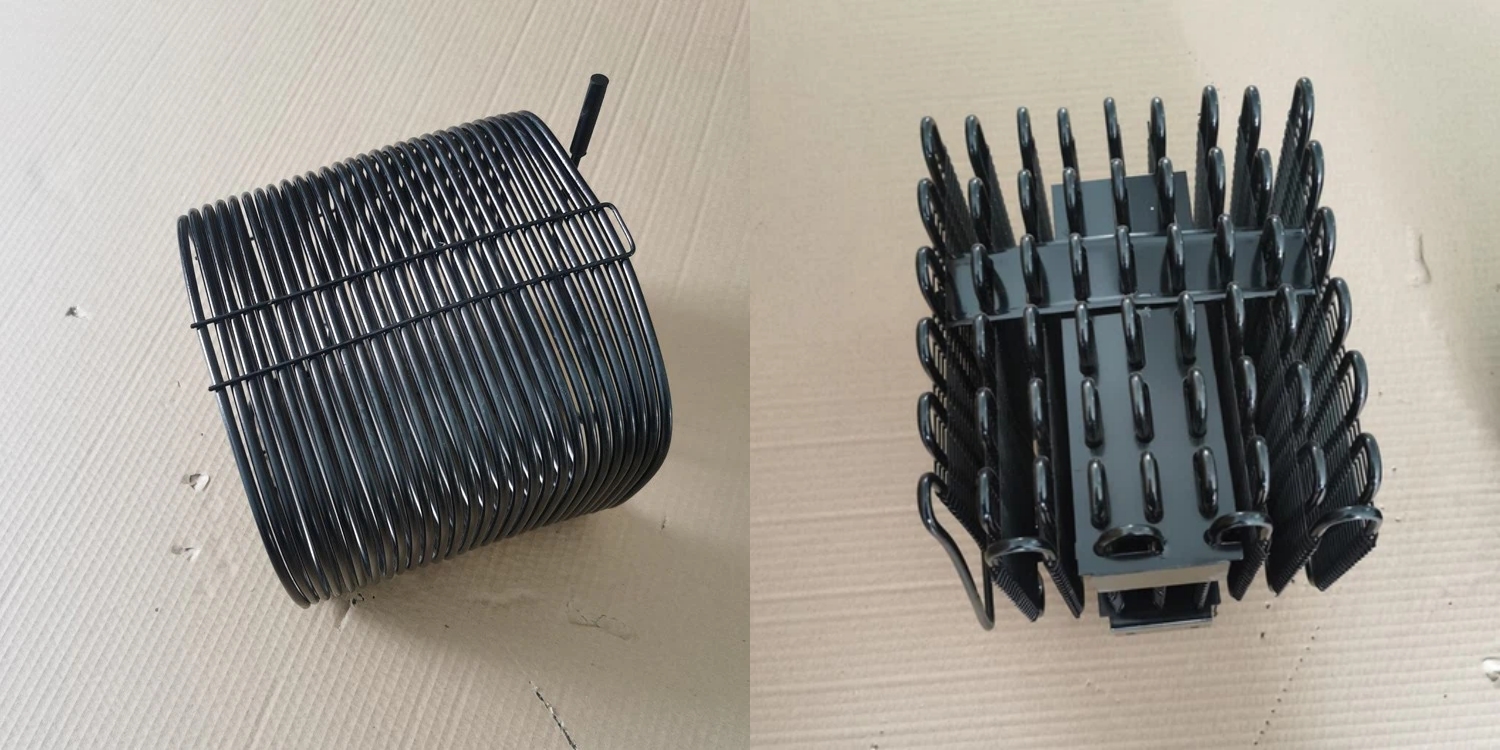

Stainless Steel Evaporator

-

Structure & Material

-

Structure: The stainless steel evaporator typically comes in vertical or horizontal designs, featuring heating elements and an evaporation chamber inside, and insulation layers outside to minimize heat loss. Its compact structure ensures a small footprint, facilitating installation and maintenance.

-

Material: The main body is constructed from premium stainless steel grades (such as 304, 316L, etc.), ensuring corrosion resistance and high temperature tolerance. Custom materials are also available based on specific application scenarios.

-

-

Operating Principle

- Liquid material enters the evaporator through the inlet, preheated to reach boiling point.

- Under the action of heating elements, the liquid rapidly vaporizes, forming steam.

- The steam rises within the evaporation chamber and undergoes heat exchange with a condenser or cooling medium, enabling material separation or purification.

- Concentrated liquid or extract is discharged through the outlet, completing the evaporation process.

-

Performance Characteristics

- Efficient Evaporation: Advanced heating technology and optimized structural design enhance evaporation efficiency and reduce energy consumption.

- Corrosion Resistance: The stainless steel material offers excellent corrosion resistance, suitable for processing various corrosive materials.

- High Temperature Tolerance: Capable of enduring continuous operation under high temperatures, ensuring equipment stability and reliability.

- Ease of Cleaning & Maintenance: The reasonable structure facilitates cleaning and maintenance, extending equipment lifespan.

-

Application Fields

- Chemical Industry: Used for evaporation, concentration, and purification of various chemical solutions.

- Pharmaceutical Industry: Extraction of drug components and preparation of medicinal solutions.

- Food Industry: Evaporation and concentration of beverages like fruit juice, milk, and alcohol.

- Biotechnology: Evaporation, extraction, and purification of fermentation broths.

-

Selection & Customization

- Selection Advice: Choose the appropriate evaporator model and specification based on material properties, evaporation capacity, working pressure, and temperature conditions.

- Customization Services: Offer comprehensive customization services, including material selection, structural design, and heating methods, to meet individual customer needs.